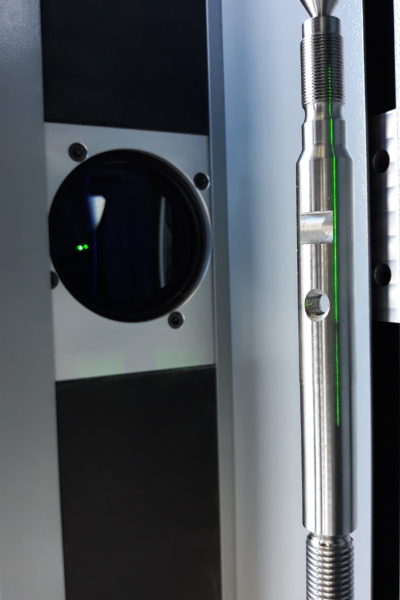

PREMION O is the automatic version of the PREMION series with a purely optical measurement system. The high-resolution matrix camera allows to measure precisely the micron on symmetrical rotating pieces.

The automated measuring process ensures reproducible and independent from user measurements. It’s designed to measure shafts directly in the workshop, next to the manufacturing machines.

APPLICATION FIELD

Every symmetrical rotating detail can be measured in few seconds and directly from the work place. That means time saving and hence an economic advantage for your production system.

CONSTRUCTION

On a stable base are installed high precision (linear) guides with an automatic moving optical system. Workpieces are placed between the adjustable tailstock and the precision spindle, led by rotary encoder.

HOW TO MAKE THE MEASUREMENT

The piece is placed and blocked between the tips by the user. The operation is intuitive and everything is managed through a touch screen.

The features are automatically measured following the scheduled measuring sequence. Measurement results are shown on the display and they even consider tolerance.

The results are saved automatically in PDF and DFQ form (Q-DAS certificate according to AQDEF).

WHAT DOES IT MEASURE

Lenght, diameter, concentricity, radius, angles and much more.

TECHNICAL FEATURES

Maximum length measurable: 400 mm

Maximum diameter measurable: 60 mm

ACCURACY DEVIATION

Length: (4 + L / 100) μm, L = length in mm

Diameter: (1 + L / 100) μm, L = length in mm