Overview

Why would you choose Nilfisk for your mechanical industry?

With over 100 years of experience, Nilfisk is one of the world leaders among machinery manufacturers. We own a wide knowledge of the specific needs of the mechanical sector. Discover the benefits of Nilfisk products and improve your company’s efficiency.

One of the biggest problem in the metalworking sector is mainteining the environment and the machines clean. Nilfisk cooperates everyday with mechanical companies worldwide in order to provide highly reliable professional solutions.

Find the solution that can improve immediately your daily tasks.

Benefits & Advantages

- It deletes machine stoppage times

- It improves the quality of the products

- More Safety

- Healthier working environment

- More productivity

Machine Tool Cleaning

Extraction of shavings and oil

The industrial vacuum is the best tool for the extraction of metal from machine tool after every work cycle. This operation keeps the machines in perfect conditions, it reduces machine stoppage times and it assures the best product quality.

Separation of shavings from oil

OIL series industrial vacuums can aspire cutting oil and emulsion with the shavings. Solid and liquid components are separated through a "macro-filtration", allowing the operator to reuse the emulsion. Regular use of OIL series vacuums helps keeping the machines in perfect conditions and it makes save money.

Aspiration of liquids

Every mechanical production company needs constantly to aspire oil, emulsion, water and chemical solutions. Aspiration of liquids means saving, not only if you want to reuse the emulsion, but also because it breaks down cleaning and maintenance expenses. For this kind of operations, Nilfisk produced VHO 200 model that can eject liquid at pressure in order to facilitate the storage of liquids in drums, or to manage the disposal properly. VHO 200 model also does aspiration and micro-filtration of solids and liquids.

Extraction of brass shavings and precious metals

Nilfisk Industrial Vacuum Solutions offers the best solution for precious metals aspiration, in order to recover every single shaving or dust during metal-working. Companies that use Nilfisk vacuums have the possibility to recover every single metal particle thanks to specific filters. That makes possible to amortize quickly the investment made for the purchase of the vacuum.

Aspiration of muds

To vacuum muds with Nilfisk is fast and easy. Triphase models have a powerful suction that permits the aspiration of heavier muds; the suction pipes don’t give resistance, and that allows a complete usage of their aspiration power. If you use the specific muds filter you can split easily muds from liquids. Filtration rate is 50/100 or 300 micron (for OIL series).

Floor cleaning for challenging applications

On factory floors it is normal to find dirt composed by dust, oil and debris, and it requires an industrial floor cleaning solution. Nilfisk’s robust floor cleaning machines can overcome these challenges easily, assuring a deep cleaning. These machines are easy to maintain and they can improve your company’s productivity.With Nilfisk you can get safe and clean floors, saving time and efforts.

Cleaning activity into the production of transportation sector is extremely diversified.

Production environments need mostly cleaning and maintenance for CNC machines (see metal working section). Into the assembly departments it’s necessary to maintain the floor constantly clean in order to ensure safety for the operator. For vehicles maintenance, from cars to ships, cleaning is the main activity.

Nilfisk is your partner during every cleaning phase in the production of means of transportation sector.

Production applications and assembly

Benefits & Advantages

- Safe working environment

- Cost saving

- Time saving

- Healthy working environment

Extraction of graphite powder or resin

Nilfisk has solutions for machines that produce refractory materials. These industrial vacuums aspire continuously the high amount of dust and waste material produced on the inside of milling cutters. Using Nilfisk’s industrial vacuums assures high quality of your products, because they aren’t contaminated by the production waste. The cleaning achieved with Nilfisk’s machines permits also a perfect maintenance of the milling cutters and a safe and dust-free environment.

Extraction of plastic, magnesium, aluminuim, lithium and sodium powder

Inflammable materials such as plastic, magnesium, aluminium, lithium and sodium represent a danger because, if triggered, they can catch fire or explode. Nilfisk produces both electric and compressed air industrial vacuums – with ATEX certification – that can work with those elements without causing sparks. Vacuums can be used in ATEX 1, 2, 21 and 22 areas.

Floor cleaning in production areas of means of transportation

Floors in production areas of vehicles require a constant cleaning.Oil and solvents must be removed from the floor in order to avoid accidents; dusty dirt can be moved from a point to another by the ventilation systems, making the environment dangerous. Nilfisk’s washer-dryer are known to be fast and efficient in making the environment safer and cleaner.

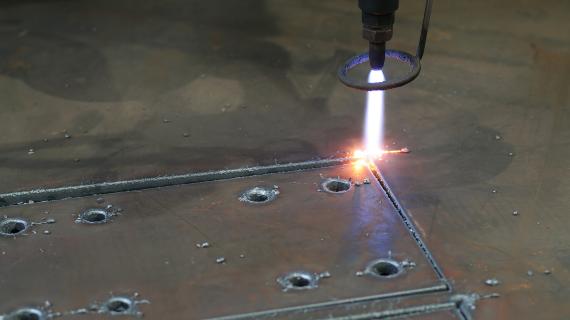

Collect dust during laser cutting

Laser cutting operations produce a fine powder similar to smoke and it is harmful for workers. On small and medium laser machines, Nilfisk’s white line works in a continuous way. The reduced dimensions allow the vacuum to integrate easily into the machine. Vacuums can be equipped with an optional activated carbon filter that removes bad odors caused by this operation. Centralized systems can be used on bigger laser cutting machines too.

Ships and planes maintenance

Extraction of paint dust

A very important part of the ordinary and extraordinary maintenance of planes and ships is the removal of the paint from walls. In order to guarantee the best operating efficiency and a good maintenance, paint dust must be collected at source, mainly for two reasons:

- paint dust is toxic and it can be harmful for the operator

- large amounts of paint dust can easily cause malfunctions in other navigation systems

This is why ATEX certificated Nilfisk vacuums are used by the main ships and planes manufacturers worldwide.

High-power vacuums, man-on-board washer-dryer and man-on-board sweepers are indispensable tools in heavy industry sector, where material recovery is important for safety and for cost control.

Nilfisk machines require a low maintenance, they are easy to use and, thanks to their outstanding performance, their investment will be amortized quickly.

Benefits & Advantages

- Collecting material in few minutes

- Cost saving

- Time saving

Applications for steel production

Production of steel pipes

Using an industrial vacuum reduces machine stoppage times during production and avoids tool’s usury. A constant use of an industrial vacuum will increase the general cleaning of about 70%. Steel pipes have to cool down after their production, which generates a steel dross that has to be removed before the next production phase.

Cleaning of large areas inside and outside foundries

Nilfisk’s series of combined machines removes easily every kind of dust with high-pressure brushes.A cleaner environment increases quickly safety and productivity.

Collecting shards from steel plates

During steel production, a big steel saw cuts automatically steel plates. In order to maintain the production clean and make maximum quality operations, sawdust must be removed. The removal of big quantities of metal shards maintains the production constantly operational.

Contattaci