- Home

- /

- Products

- /

- Testo | Professional Measuring...

- /

- Testo | Thermal Imaging...

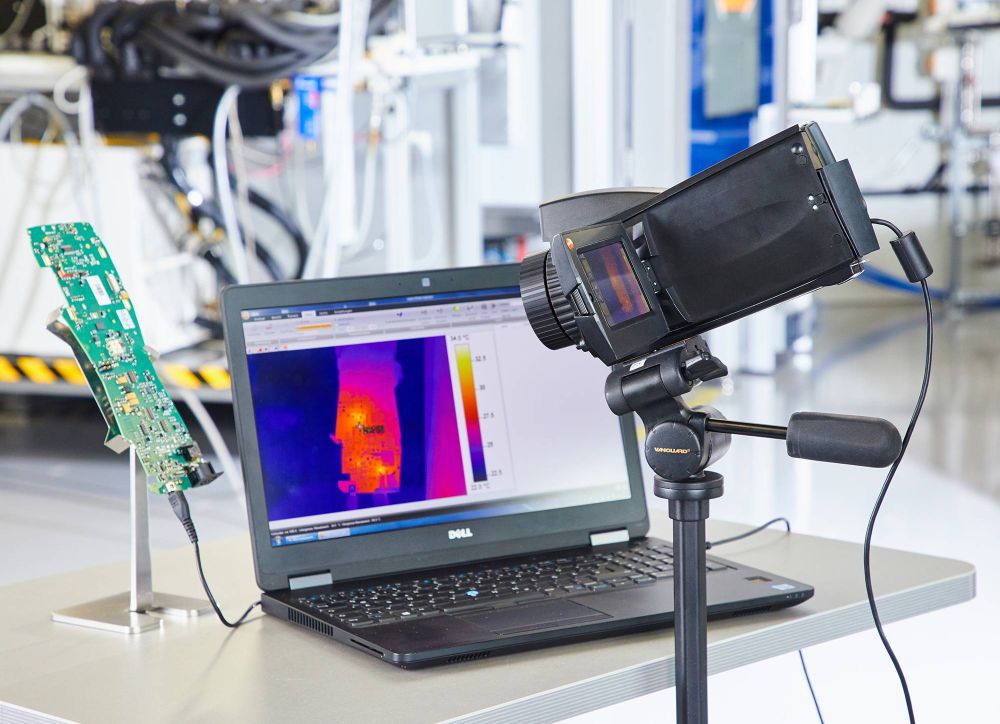

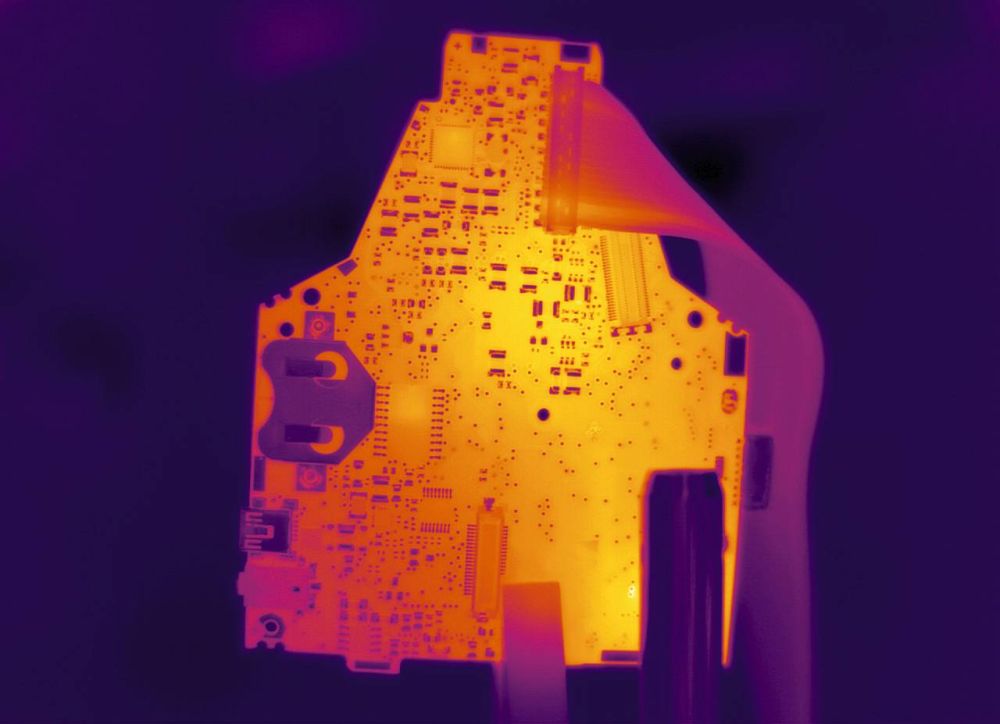

Thermal imagers: more efficient development processes and faster malfunction detection into the Research and Development sector

Using a high resolution Thermal Imaging camera you can:

- Locate in a targeted way programmed break points

- Detect in real time any anomalies and track cooling and heating processes

- Make security checks on electronic components

- Analyse accumulations and losses of heat on printed circuit boards and optimise development processes

Testo Thermal Imaging cameras can help you with complex thermal tasks during the development stage of your products.

Electronic components assembled on printed circuit boards are smaller and smaller and close one to another. Here’s how Testo thermal imaging cameras can make you save time and money in the R&D sector:

- It visualises precisely temperature distribution thanks to the focus distance of ≥ 10 cm

- It analyses easily and quickly the relationship between hotspots and heat dispersion

- It optimises heat dissipation

Temperature check on a machine tool

Temperature check during quality control

Features of Testo Thermal Imaging Cameras

The purchase of a thermal imager is a smart investment. Especially if you choose Testo Thermal Imaging Cameras, because they offer you the best quality-price ratio of their category.

In this way you can make the most of infrared thermography’s features for your purposes:

Temperature check on R&D components

Temperature check for maintenance

- Home

- /

- Products

- /

- Testo | Professional Measuring...

- /

- Testo | Thermal Imaging...

IFOV warner: Sempre la distanza giusta

IFOV warner: Sempre la distanza giusta