TA-Center

TA-CENTER boring and cutting heads are designed to be used on machines with automatic tool change.

The control of the feed, the tool slide and the tool position is controlled by a U-DRIVE motor drive. This group is managed directly by an axis called "U" of the numerical control of the work center.

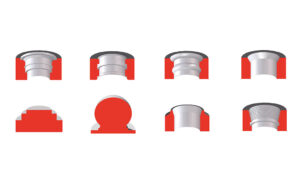

A working center so arranged will allow to solve a series of different processes such as internal and external turning, channels, conical boring also variable, convex and concave radii, cylindrical and conical threads, Phonographic spirals and spherical processing.

The possible application on machines that do not allow the connection to a CNC axis, can be done by managing the motor of the U-DRIVE motorization group with the U-CONTROL positioner with REMOTE-CONTROL wireless.

The positioner can be connected to the M functions of the machine control to receive start signals of the various operations programmed on the REMOTE-CONTROL. With the machines equipped with the KIT U-CONTROL WIRELESS, it is not possible to perform spherical machining.

Also available in semi-standard version TAC-HP suitable for mass production in the automotive sector.

.

U-DRIVE

The U-DRIVE motor drive unit must be mounted on the machining center next to the spindle in order to ensure the mechanical connection of the motorcycle socket to the TA-CENTER head. The main components of the U-DRIVE are:

- basic body

- servo motor

- the mechanical unit, prepared with air inlet connection for cleaning of the motorcycle outlet, for automatic coupling to the TA-CENTER.

The U-DRIVE motorization unit can take different configurations depending on the application on the machining center:

- horizontal

- horizontal at 90 o'clock

- vertical.

Application of the U-Drive

The U-DRIVE can be easily positioned on the machine with a support plate to adapt to the machine connected and attached to the holes on the front of the spindle. Other special configurations can be provided on request.

COMMAND UNIT

The TA-CENTERS are applicable to work centers and can be managed directly from an axis called "U" of numerical control. The possible application on machines that do not allow the connection to a CNC axis, can be done by managing the motor of the control unit with a practical U-CONTROL with wireless REMOTE-CONTROL.

The positioner can be connected to the M functions of the machine control to receive start signals of the various operations programmed on the REMOTE-CONTROL.

REFRIGERANT LIQUID SUPPLY

In the TA-CENTER the coolant comes out of two adjustable nozzles placed on the side of the sled after crossing the cone and the rotating head. This ensures a longer insert life, faster-cutting speed, and good surface finish.

The centralized supply of the coolant does not damage the TA-CENTER whose internal labyrinths are protected by sealing rings. It is advisable not to exceed 40 BAR of pressure.

BALANCING

The TA-CENTER heads have been designed with two counterweights for automatic balancing, which move in the opposite direction to the slide allowing to work at a high number of revolutions without appreciable oscillations.

TOOLS APPLICATIONS

Standard tools can be mounted on the tool holders to perform simple and multiple machining of internal and external turning, conical bore also variable, concave and convex radii, channels, cylindrical and conical threads, faces, phonographic spirals.