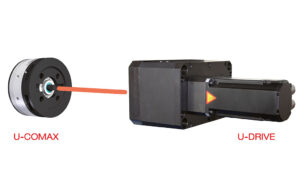

U-Comax

Axially controlled boring and milling heads, numerically controlled on transfer machines and operating units, which apply rigidly to the spindles of the machines.

General features

U-Comax heads are intended for use on transfer machines, operating units, and special machines. The control of the advancement of the tool slide, even during rotation, is controlled by a U-Drive motorization unit mounted at the rear of the spindle and managed directly by the CNC of the machine tool. U-Comax heads are used for internal, external and sub-quadrant brazing, internal and external turning, channels, phonographic spirals, cylindrical and conical threads, conical reamers, even variable, concave and convex radii, by interpolation with the other axes of the machine.

U-DRIVE U-COMAX

The U-Drive motor for the U-Comax heads is mounted at the rear of the machine spindle, managed by a numerical control axis and mechanically connected to the U-Comax head motion socket with a drive shaft that runs through the spindle of the machine itself.

The U-Drive motor can take on different configurations depending on the application and the constructive shape of the machine.

REFRIGERANT LIQUID SUPPLY AND LUBRICATION

Inside the rotating body of the U-COMAX, there are canalizations that allow the passage of the coolant liquid from the spindle of the machine up to two adjustable nozzles placed beside the slide. This ensures longer insert life, faster-cutting speed and good surface finish. The central supply of the coolant does not damage the U-COMAX. It is advisable not to exceed 40 BAR of pressure.

The U-Comax is designed for automatic lubrication with nebulized oil of the slide guides and the mother screw.

BALANCING

The U-COMAX heads have been designed with two counterweights for automatic balancing, which move in the opposite direction to the slide allowing to work at a high number of revolutions without appreciable oscillations.