- Casa

- /

- Products

- /

- Exameca Mesure

- /

- Measuring machines for shafts

PERFECT FOR PRODUCTION

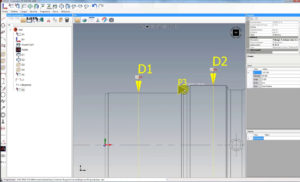

Combodim, Unidim and Optodim special design allows you to monitor the production line and to receive a quick feedback about any deviation of the working tools.

It is also the best way to speed up laboratory measurements using our in-situ machines, saving a lot of time.

The machines are equipped with functions for temperature compensation that ensure reliable and precise results.

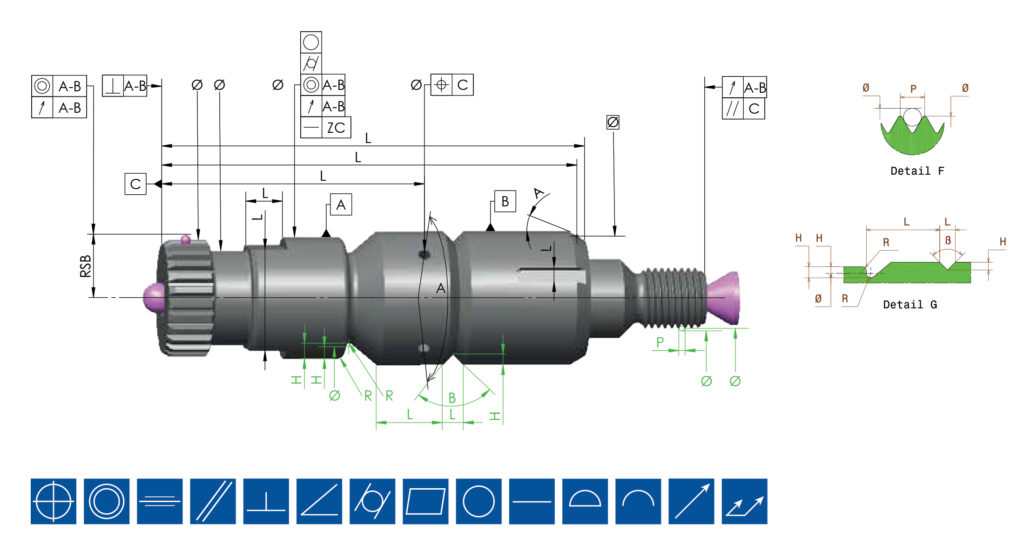

OPTICAL SENSORS

An interesting aspect regarding these machines for shafts measurement is the possibility to add optical sensors (optional), which provide a complete check of every detail like radius, grooves, chamfers, and all those profile forms that can’t be measured with typical contact probes.

Optical sensors have three main benefits: programming without drawings, scanning prototype parts, and measuring in shorter cycle times in comparison with contact mode.

FASTER CONTACT PROBES

It doesn’t matter how contaminated the piece to measure is; Combodim, Optodim and Unidim assure a micrometric measurement thanks to length probes and diameter probes (contact measurement).

Due to these machines the operator will get an easier work management and he will be staying in front of the machine just the time to place the workpiece and start the measuring cycle.

Combodim, Unidim and Optodim will take care of the rest.

LONG-TERM FLEXIBILITY

Multi-sensor machines are the key to fulfill your needs from the first to the last operation using one single machine.

Our Combodim is the most rational choice regarding annual manual calibration, so you can save resources and avoid using various instruments that sometimes are designed to check just one feature.

We are available to make dimensional modifications to our machines.

MEASUREMENT FUNCTIONS

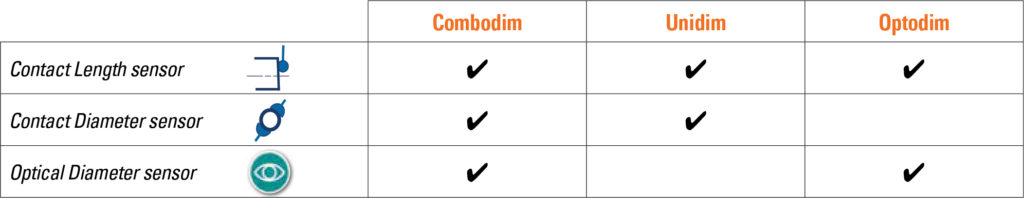

VARIANTS AND OPTIONS

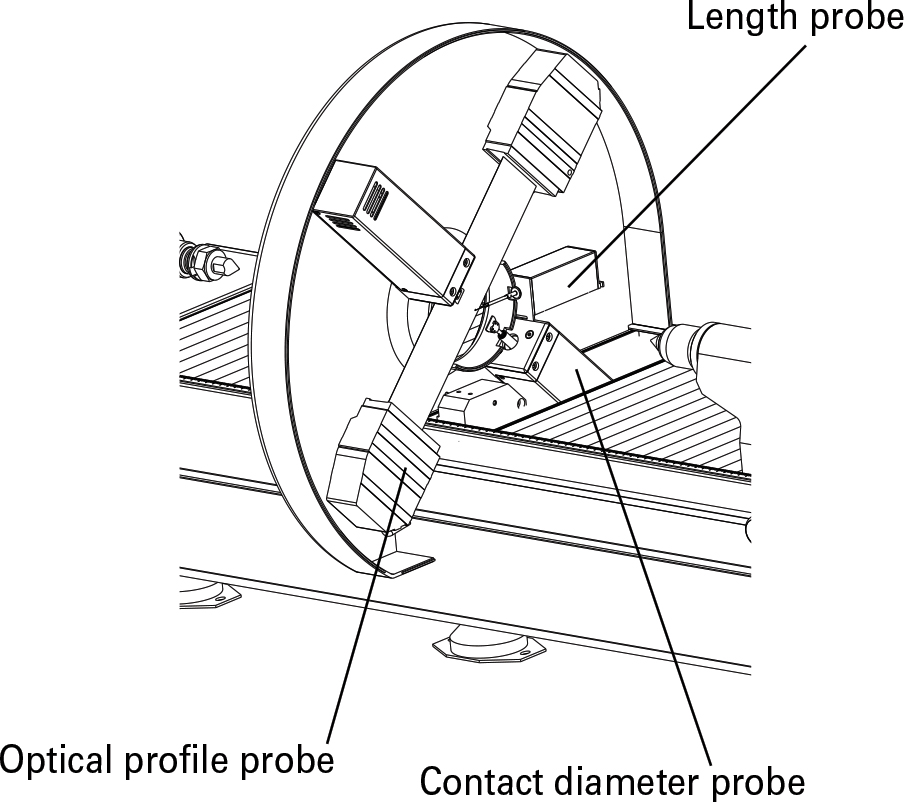

Lenght probe on our machines ensures the highest accuracy on: depth and angle, key slots, location of holes, flat surfaces, axial runout etc.

Contact diameter probe measures: runout diameter, coaxiality, circularity, cylindricity (only Unidim and Combodim).

Optical profile probe (only Optodim and Combodim) scans and controls all the features that can’t be controlled through contact measurements: radius, grooves, chamfers, profile shape, tolerances within a range…

INTEGRATED FUNCTIONS

APPLICATIONS FOR SHAFT

Thanks to our machines almost all the features of the shaft can be measured. Besides, equipped with the latest OBD System, Combodium, Unidim and Optodim can offer you the best in terms of versatility: a whole package for all your production needs.

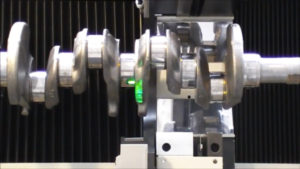

CAMSHAFT

Cam follower is the function that permits to measure the whole cam profile during its rotation. Concave camshafts can also be measured with roller wheels.

OTHER APPLICATIONS

These measuring benches are designed to measure more than standard shafts.

Therefore, our machines control a wide range of velocity joints (as shown), injectors, electrical motor crankshafts, steering shafts and racks, turbine shafts etc.

OBD SYSTEM (OPTIONAL)

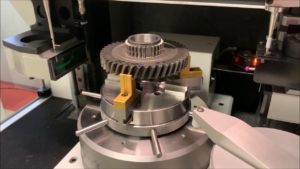

The capacity of Unidim and Combodim increases with the integration of an OBD contact probe.

The use of six different spheres allows the machine to do additional functions such as:

- OBD on gears and spline

- Pitch diameter

- Root diameter

- Outer diameter

PIN SYSTEM

Small accessory that allows the machine to check the pitch diameter on a spline by comparison.

CENTER TIPS

It’s possible to customize center tips in order to satisfy all your needs.

LASER INDEX

Laser light beam projector, allowing the operator to easily and radially index the part to be measured.

BARCODE SCAN

Useful in production, and more convenient for the operator, it guarantees an automatic recognition of the relevant programming and to record all traceable data.

T SENSOR

workpiece temperature sensor provides a complete report of the temperature and the thermal expansion of the workpiece in real time as it’s being checked.

Ambient temperature sensor is a standard feature.

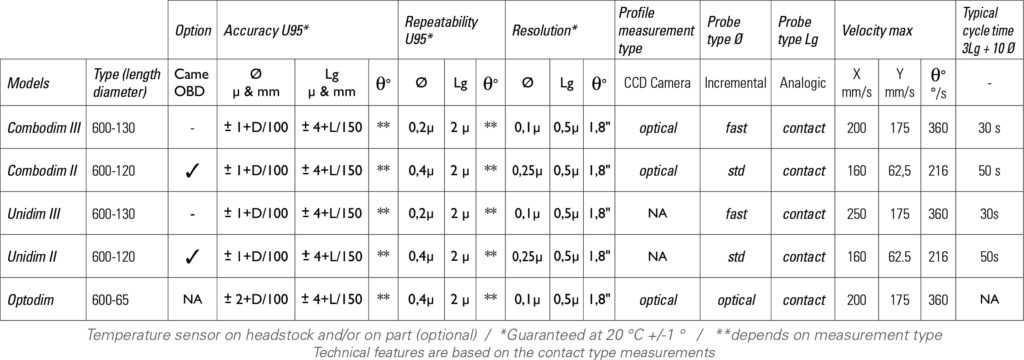

TECHNICAL FEATURES

CALIBRATION

Automatic and integrated calibration zone/ depending on time and/or temperature

POWER SUPPLY

230 or 400 VAC, 50 Hz

OPERATING CONDITIONS

Humidity ≤70% – Temperature Min. 10°C / Max. 45°C

NOISE LEVEL

≤70 dB (A)

ALL OUR SOLUTIONS

COMBODIM – UNIDIM – OPTODIM

COMBODIM XL – UNIDIM XL

INTERDIM 3D – 4D – 5D

HMI – ATLAS

- Casa

- /

- Products

- /

- Exameca Mesure

- /

- Measuring machines for shafts