- Casa

- /

- Products

- /

- Exameca Mesure

- /

- Software and Solutions for...

FASTER

Exameca measure optimized their own standard solutions in order to reach the complete check of the particulars directly in the production line, ensuring a reduction of the defective parts in the production. It doesn’t matter how contaminated the part is, our machines assure a micrometric measurement thanks to different sensors installed on board.

MORE CONNECTED

Our way to see flexibility doesn’t mean having probes scattered everywhere in order to monitor the production status.

We created a complete interface to communicate with your daily working tools, from robots to machine tools, with the purpose to answer 4.0 industry needs.

An example of automated control in production with our measuring machines

MEASURING SOLUTIONS

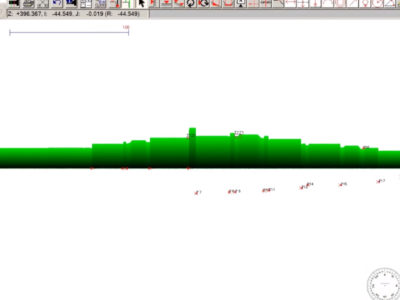

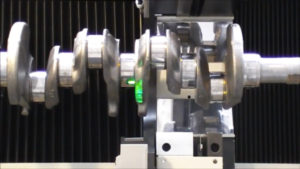

TRANSMISSION SHAFTS FOR ELECTRIC MOTORS

With our machines it is possible to control the receiver (bearing) of the transmission shafts using a dedicated optical probe.

SLEEVES

Check of the tooth simmetry, coaxiality, and many other important characteristics that are hard to detect in production.

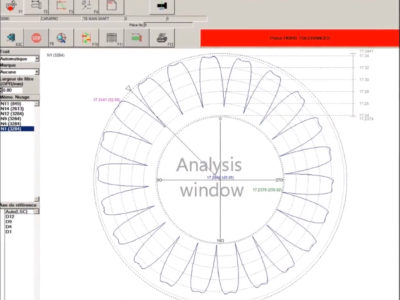

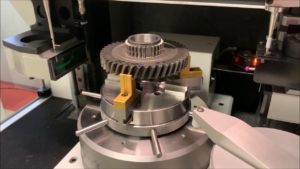

GEARS

Combined examination with ball touch probes (with different diameters) and many optical probes.

BRAKE DISKS

Thanks to our machines we are able to measure all the brake disks characteristics.

CONSTANT-VELOCITY COUPLINGS

Inspection of a wide range of features like coaxiality, eccentricity, etc.

AERONAUTICAL SHAFTS

Combined examination with ball touch probes (with different diameters) plus optical probes.

INKECTOR NOZZLES

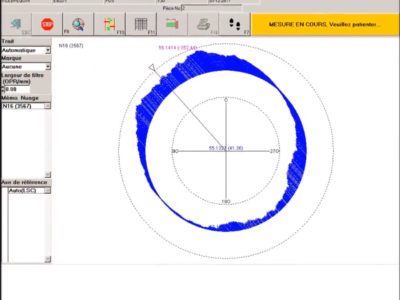

Achievement of a circularity tolerance within 6 μm.

PULLEYS

Optical measurement of the outer parts of the pulleys.

SOFTWARE

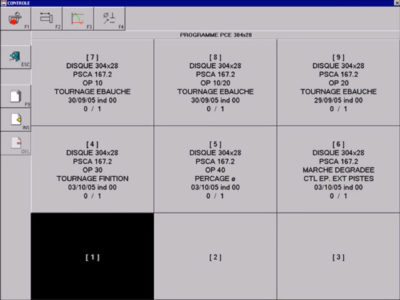

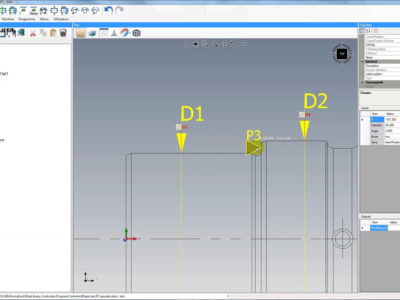

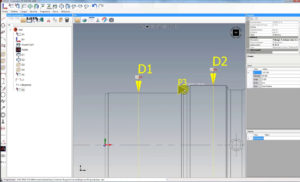

HMI

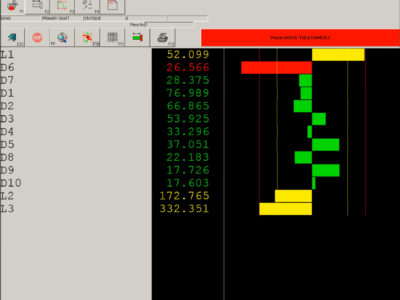

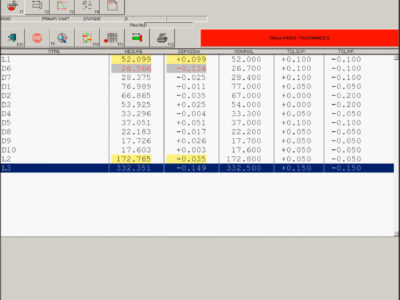

Current software used by Exameca machines, with intuitive interfaces and automatic error detection:

– HMI permits to visualize the correct piece placement into the machine using pictures uploaded during programming

– The measured values are saved and they can be exported using PDF report

– Graphic visualization of the latest features measured

– QDAS format for files

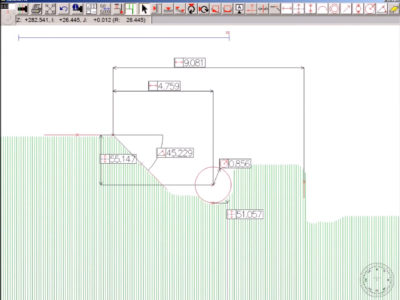

ATLAS

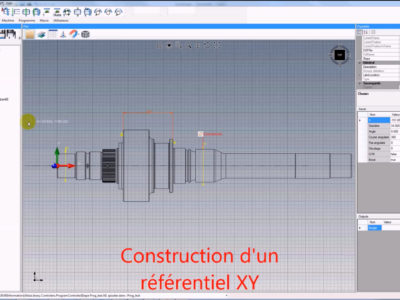

The new Exameca software (release expected within the next months) has some differences compared to the HMI Software:

– Multiuser and multilayer

– Even more intuitive icons

– One click setup

– Overview of the method and the values of the selected characteristics

– Possibility of creating more templates of the same detail, assuring the same process or measuring method

– Windows standard functions (copy, paste, cut, undo, re-do etc.)

– Multilingual software

– 2 ways of programming:

• from an upload of CAD file of dxf or dwg format

• from a scan of the part (if optical sensors are equipped)

ALL OUR SOLUTIONS

COMBODIM – UNIDIM – OPTODIM

COMBODIM XL – UNIDIM XL

INTERDIM 3D – 4D – 5D

HMI – ATLAS

- Casa

- /

- Products

- /

- Exameca Mesure

- /

- Software and Solutions for...